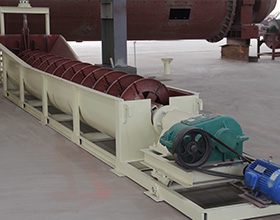

Rotary Dryer

Processing ability:20–150 t/h

Brief introduction:

The Rotary Drier is widely used in the field of building materials, metallurgies, chemical industry, cement and so on.

Applications:

The Rotary Drier is widely used in the field of building materials, metallurgies, chemical industry, cement and so on. It can dry slag, coal powder, mining powder, clay, sand, limestone and so on. It is made of rotary body, lifting blade, driving device, supporting device etc. The dryer has advantages of reasonable structure, high efficiency, low energy consumption and convenient for transportation.

Features:

a) Reasonable structure;

b) Low consumption, energy saving;

c) Easy to maintain, easy to operate;

d) Quick deliveries, solid construction;

e) Novel design, fine manufacturing;

f) Customized for every application;

g) Best price on the market.

Working principle:

Rotary dryers consist of a horizontally inclined rotating cylinder. Material is fed at one end and discharged at the other end. In direct-type rotary dryers, hot gases move through the cylinder in direct contact with the material, either with or against the direction of its flow. The cylinder is equipped with flights, which lift the material and shower it down through the hot gas stream.

Technical data:

| Spec. (Dia.x Length mm) |

Volume(m³) | Capacity (t/h) | Gradient(%) | Highest Inlet Air Temperature(℃) |

Rotate Speed(r/min) | Main Motor(kw) |

| Φ600x6000 | 1.7 | 0.5-1.5 | 3~5 | 700~800 | 3~8 | 3 |

| Φ800x8000 | 4.1 | 0.8-2.0 | 3~5 | 700~800 | 3~8 | 4 |

| Φ800x10000 | 5.1 | 0.8-2.5 | 3~5 | 700~800 | 3~8 | 4 |

| Φ1000x10000 | 7.9 | 1.0-3.0 | 3~5 | 700~800 | 3~8 | 7.5 |

| Φ1000x12000 | 9.4 | 1.2-3.2 | 3~5 | 700~800 | 3~8 | 11 |

| Φ1200x8000 | 9 | 1.9-2.4 | 3~5 | 700~800 | 3~8 | 7.5 |

| Φ1200x10000 | 11.3 | 2.2-3.0 | 3~5 | 700~800 | 3~8 | 7.5 |

| Φ1200x12000 | 13.6 | 2.4-3.2 | 3~5 | 700~800 | 3~8 | 7.5 |

| Φ1500x12000 | 21.2 | 4.5-5.7 | 3~5 | 700~800 | 2~6 | 15 |

| Φ1500x14000 | 24.7 | 5.3-6.6 | 3~5 | 700~800 | 2~6 | 15 |

| Φ1500x16000 | 26.5 | 5.7-7.1 | 3~5 | 700~800 | 2~6 | 15 |

| Φ1800x12000 | 30.5 | 6.5-8.1 | 3~5 | 700~800 | 2~6 | 18.5 |

| Φ1800x14000 | 35.6 | 7.6-9.5 | 3~5 | 700~800 | 2~6 | 18.5 |

| Φ1800x16000 | 40.7 | 7.8-10.2 | 3~5 | 700~800 | 2~6 | 18.5 |

| Φ2000x18000 | 56.5 | 8.4-12.3 | 3~5 | 700~800 | 1.5~6 | 22 |

| Φ2000x20000 | 62.8 | 9.0-13.6 | 3~5 | 700~800 | 1.5~6 | 22 |

| Φ2200x16000 | 60.8 | 11.4-15.8 | 3~5 | 700~800 | 1.5~6 | 22 |

| Φ2200x18000 | 68.3 | 12.8-16.2 | 3~5 | 700~800 | 1.5~6 | 22 |

| Φ2200x20000 | 75.9 | 13.0-16.5 | 3~5 | 700~800 | 1.5~6 | 30 |

| Φ2400x16000 | 72.3 | 13.5-16.9 | 3~5 | 700~800 | 1.5~5 | 37 |

| Φ2400x18000 | 81.4 | 17.4-21.7 | 3~5 | 700~800 | 1.5~5 | 45 |

| Φ2400x20000 | 90.4 | 19.3-24.1 | 3~5 | 700~800 | 1.5~5 | 55 |

| Φ2600x24000 | 127.4 | 27.2-34.0 | 3~5 | 700~800 | 1.5~5 | 75 |

| Φ2600x28000 | 148.6 | 28.6-36.2 | 3~5 | 700~800 | 1.5~5 | 75 |

| Φ3000x20000 | 141.3 | 30.1-37.7 | 3~5 | 700~800 | 1.5~5 | 90 |

| Φ3000x25000 | 176.6 | 37.7-47.1 | 3~5 | 700~800 | 1.5~5 | 90 |

SENT INQUIRY

Crushing Equipment

- Jaw Crusher

- Impact Crusher

- CS Cone Crusher

- Spring Cone Crusher

- Hydraulic Cone Crusher

- Heavy hammer crusher

- VSI Sand Maker

- PCL Sand Maker

- High-efficiency Fine Crusher

- Double Roller Crusher

- Vertical compound crusher

- JCE European Jaw Crusher

- Small Jaw Crusher

- Hammer Crusher

- Shredding Machine

Powder Grinding Mills

- Raymond mill

- YGM High-pressure Grinding

- HGM Micro-powder Grinding

- High Efficiency Classifier

- Energy Saving Ball Mill

- Wet pan mill

Beneficiation Equipment

- Energy Saving Ball mill

- Rotary Dryer

- Rotary Kiln

- Magnetic Separator

- Dry Magnetic Separator

- Flotation Machine

- Gold concentrator

- Spiral Classifier

- Shaking Table

- Spiral Chute

- Tailing Recycling Machine

- Jigging machine

Mobile Crushing Plant

- Mobile Jaw Crushing Plant

- Mobile Impact Crushing Plant

- Mobile VSI sand making plant

- Mobile Cone Crushing Plant