Home > Product > Shredding Machine

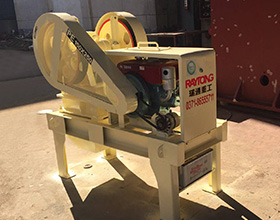

Shredding Machine

Processing ability:2–25 t/h

Brief introduction:

Shredding machine also called shear-type shredding machine,by cutting 、tearing and extrusion materials to achieve smaller size.

Applications:

plastic pipe, plastic board, wood, woven bags, tire, aluminum cans,metal waste

Shredding machine also called shear-type shredding machine,by cutting 、tearing and extrusion materials to achieve smaller size.Shredding machine is widely used for shredding big size of hollow containers(Clinker bucket,etc) and variety of metal mixture scraps,etc.Shredding machine adopts a unique rotary shaft structure and rotary type blades at low speed and high torque production process ,it does not appear wrapped around the shaft, or stuck equipment phenomenon,resulting in improved production efficiency. Thickness and number of blades can be replaced according to different materials.

1. Variety of hollow containers: Plastic beverage cans, plastic buckets, iron cans,packing boxes.

2. Waste household appliances: TV, washing machine, refrigerator shell

3. Pipe: Large pipes, tubes, PE pipes

4. Waste Template: wooden pallets, plastic pallets,truck pallet

5. Waste Tires: car tires, truck tires

6. Metal Scraps : car shell,Aluminum die casting scraps, engine shell, gear boxes ,lead as well as the steel plate with less than 5mm thickness.

7. Food wastes,household garbage, animal carcasses, RDF derivatives, medical waste, biological straw, garden garbage

8.Rubber head materials,paper plant twisted rope.

Features:

1. Double shaft shredding machine is suitable to process very big size of plastic material, such as plastic pipe, plastic board, wood, woven bags, tire, aluminum cans,little diameter of copper wire and pressing plastic film which the single Shaft plastic shredder can not process.

2. The machine with big feeding mouth, it can put the big plastic product freely.

3. The rotary blade and cutting blade and blade edge with special design, it can get very high efficiency and high capacity

4. The machine is control by PC system . The knife can rotated in opposite direction, and also can close automatic if something unexpected happen, with very high safety service

5.The knife material is made of alloy steel with high quality and long lifetime.

6.Low speed,low noise,little dust.

Working principle:

Materials are fed to shredding box with shredding blades by feeding system,then after cutting 、tearing and extruding by blades to get smaller size.Finally,the products discharging from the bottom.

Structure

Shredding machine is made of shredding blade group, bearing box, frame, feeding systems, power systems, electrical control systems,etc.

1.Main unit of shredding machine

Main parts adopt high quality steel welding,to ensure the stability in long heavy-duty working.

2.Bearing / Seal

Bearing seat adopts patent split open type, quickly remove the moving blade,fixed blade,bearing,etc.The maintenance and replace of blades are very convenient.

3.Moving Blade / Fixed Blade

Blade material is Chromium silicon alloy.Fixed blade uses patented hook type installation,to optimize the replace function of blade and make the maintenance, replacement of blade more efficient.

4.Blade Shaft

Blade shaft adopts high-strength heavy-duty special steel to process, more reasonable fit for the blades to provide a strong impetus.

Technical data:

| Model | BC-1900 | BC-1500 | BC-1200 | BC-1000 | BC-600 |

| Main shaft power(kw) | 4-90*2 | 4-45*2 | 4-37*2 | 4-30*2 | 4-15*2 |

| Main shaft speed(r/min) | 18-25 | ||||

| Capacity(t/h) | 10-25 | 8-18 | 6-15 | 5-10 | 2-5 |

| Feeding Power(kw) | 3-4 | 3-4 | None | ||

| Blade Qty(PCS) | Different materials, the Qty of blade claws and blades are different, can be customized. | ||||

| Blade Dia.(mm) | Φ600 | Φ550 | Φ400 | ||

| Output Size(cm) | 3-10 | ||||

| Hopper Size(m) | 2.3*2 | 2*2 | 1.4*1 | 1.2*1 | 0.82*0.9 |

| Overall Dimension (L*W*H)(m) | 8*2.5*2.4 | 4*1.7*2.4 | 3.2*2*1.9 | 3*2*1.9 | 2.6*2*1.9 |

SENT INQUIRY

Crushing Equipment

- Jaw Crusher

- Impact Crusher

- CS Cone Crusher

- Spring Cone Crusher

- Hydraulic Cone Crusher

- Heavy hammer crusher

- VSI Sand Maker

- PCL Sand Maker

- High-efficiency Fine Crusher

- Double Roller Crusher

- Vertical compound crusher

- JCE European Jaw Crusher

- Small Jaw Crusher

- Hammer Crusher

- Shredding Machine

Powder Grinding Mills

- Raymond mill

- YGM High-pressure Grinding

- HGM Micro-powder Grinding

- High Efficiency Classifier

- Energy Saving Ball Mill

- Wet pan mill

Beneficiation Equipment

- Energy Saving Ball mill

- Rotary Dryer

- Rotary Kiln

- Magnetic Separator

- Dry Magnetic Separator

- Flotation Machine

- Gold concentrator

- Spiral Classifier

- Shaking Table

- Spiral Chute

- Tailing Recycling Machine

- Jigging machine

Mobile Crushing Plant

- Mobile Jaw Crushing Plant

- Mobile Impact Crushing Plant

- Mobile VSI sand making plant

- Mobile Cone Crushing Plant