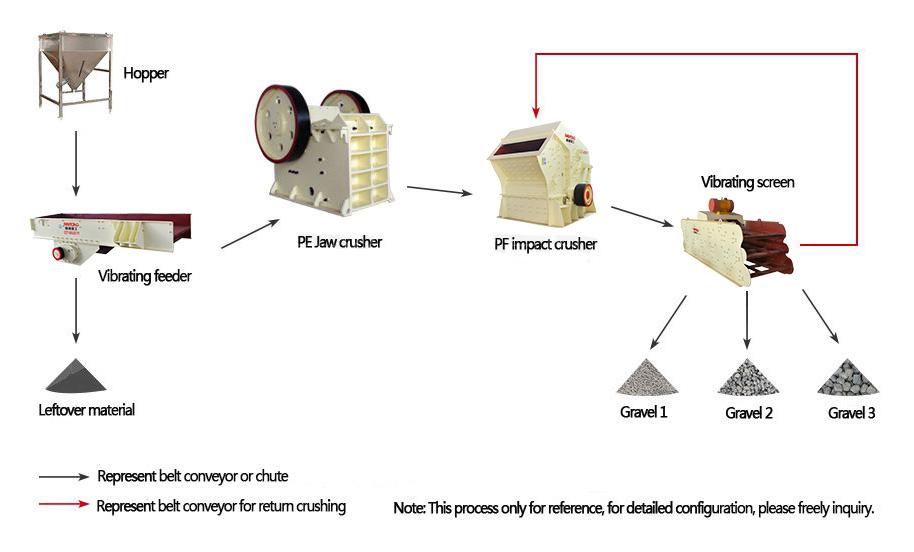

Stone crushing plant process introduction:

Stone crushing plant mainly composed with vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor and electrical controlling system. Capacity can be 30-1000t/h. For different requirements on finished products sizes also can equip with cone crusher, VSI sand maker and dust remove system.

Raw materials are evenly and continuously conveyed into jaw stone crushing equipment for primary crushing. The crushed stone materials are conveyed to impact crusher (or cone crusher) by belt conveyor for secondary crushing before they are sent to vibrating screen to be separated. After separating, qualified materials will be taken away as final products, while unqualified materials will be carried back to the impact crusher (or cone crusher) to re-crush.

| Equipment Configuration | ||||||

|---|---|---|---|---|---|---|

| Capacity Model Product | <50tph | 50-80tph | 80-120tph | 150-220tph | 180-250tph | 250-450tph |

| Vibrating feeder | ZSW850*3000 | ZSW850*3000 | ZSW960*3800 | ZSW1100*4200 | ZSW1100*4200 | ZSW1300*4900 |

| Jaw crusher | PE400*600 | PE500*750 | PE600*900 | PE750*1060 | PE900*1060 | PE900*1200 |

| Impact crusher | PF1007/1010 | PF1010 | PF1214/PF1315 | PF1320/PF1214*2 | PF1415/PF1315*2 | PF1320*2 |

| Or Cone crusher | PYB900 | CS75 | PYB1200 | CS160 | PYB1750 | CS160*2 |

| Vibrating screen | 3YK1548 | 3YK1860 | 3YK2160 | 3YK2460 | 3YK2460 | 3YK2460*2 |